Clean Air Systems for Lean Manufacturing

Whether you call it lean manufacturing or Just-in-Time (JIT) manufacturing, eliminating waste isn’t a new concept for bottom-line minded manufacturers.

But, it isn’t easy to reduce operating costs while creating more value for your customers.

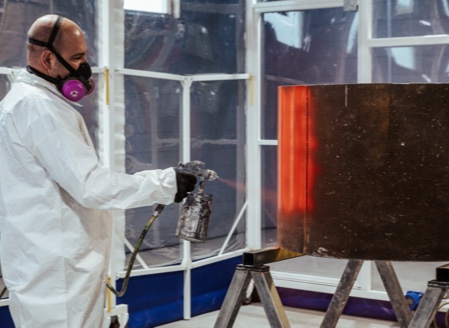

This is especially the case for welding, surface preparation, sanding, painting, or other processes that produce harmful air contaminants and create production bottlenecks for larger construction projects.

What if you had a portable, clean air solution to protect your employees from indoor airborne hazards while saving valuable floor space? Rather than wasting man-hours moving tasks to specific productions cells, you could bring the clean air to each workpiece.

Modular Industrial Air Filtration for Lean-Minded Manufacturers

Duroair retractable enclosures and industrial air filtration systems for lean manufacturing protect against dust and particulates to prevent rework delays and extend the life of valuable equipment. Each system can be engineered to work with one-piece flows and cellular processes.

Our clean air solutions are designed with lean manufacturing best practices, including:

- Spray and paint booths that combine Duroair’s vented DuroCap™ air purification system with our patented Taper Draft Airflow technology to improve drying times and prevent overspray

- Four-stage filtration dust collectors that go beyond OSHA compliance to capture 100 percent of air particulates

- Cellular clean rooms with DuroPure™ non-vented filtration that recycle air without the need to exhaust contaminants to the outside, eliminating the need for costly air makeup

- Portable enclosures that pair with any Duroair filtration system and retract to less than 20 percent of the extended length

Duroair Products for Lean Manufacturing

Our products are customized to meet your exact needs and specifications ensuring both a safe and productive work environment.