Painting & Coating Requires Flexibility for Clean Air Control

Flexibility is key to creating controlled, safe, and productive work environments during painting and coating for maintenance, repair, and operations (MRO). This is especially the case in high-mix/low-volume (HMLV) manufacturing environments where constant changes in workflows make it challenging to meet your indoor air quality requirements.

Contact Us

Bring Clean Air to Your Painting and Coating Operations

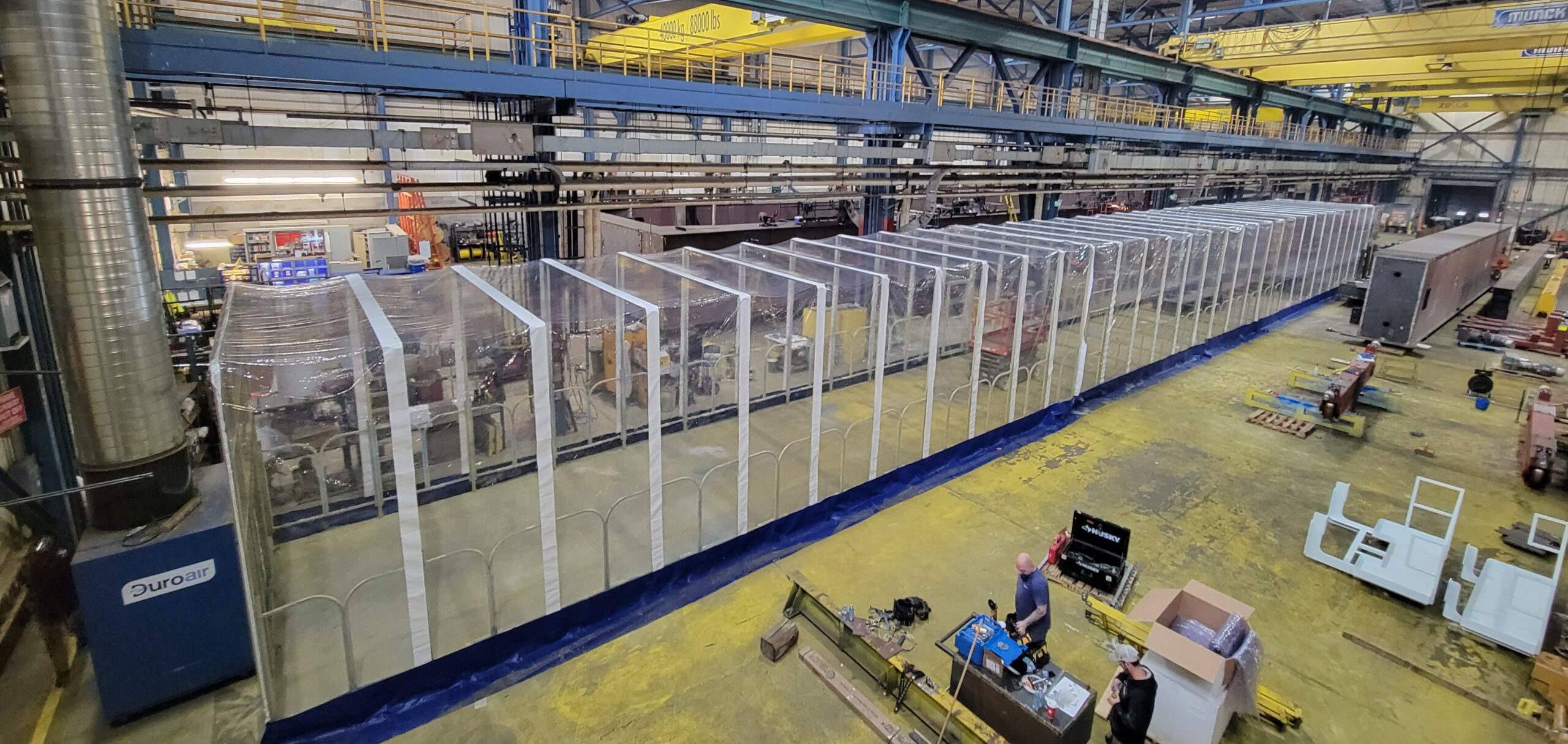

Duroair combines our DuroRoom™, DuroCap™, and DuroPure™ technologies into one industrial air cleaning system to make sure you get your clean air requirements right every time.

Our portable paint booths offer flexible, compliant clean air solutions for painting and coating processes that bring the benefits of clean air to each workplace.

Duroair’s portable, retractable enclosure with DuroCap™ vented and DuroPure™ recirculating air filtration systems can be custom tailored to your facility workflows. Our solutions prevent costly surface rework from contaminants, while capturing toxins like VOC’s, hexavalent chromium, and isocyanates.

Duroair’s painting and coating fume exhaust systems provide:

- Faster drying times and improved overspray control with Duroair’s patented Taper Draft Airflow Technology

- Efficient material handling with full use of overhead cranes for moving large workpieces

- Increased flexibility within a shop workspace for alternating between intermittent painting and coating processes and other operations

- Optimized floor space utilization using our retractable enclosure, DuroRoom™, for other revenue generating activities

- 99.4% of airborne particulates captured with DuroCap™ vented solution

- Unmatched employee protection with DuroPure’s™ high-efficiency, six-stage filtration process that captures 99+% of airborne particulates, gases, and vapors

Technical Specifications

- DuroCap™ two-stage and DuroPure™ six-stage air filtration ranging from 13,500 CFM to 100,000 CFM and beyond

- Filtration capable of capturing hexavalent chromium superior to NESHAP 319

- Interlocked, fan-spray system prevents user from spraying contaminants unless fan is running

- Air quality monitor and magnehelic gauge indicate when filters require changing

- Integrated VOC monitor keeps levels below 50 ppm during the eight hour weighted time mandated by OSHA

- Custom, spark-proof fan designed specifically for coating applications

- NFPA 33 compliant motor and electrical systems work outside of the air stream

Contact Us

Duroair Products for Painting & Coating

Our products are customized to meet your exact needs and specifications ensuring both a safe and productive work environment.