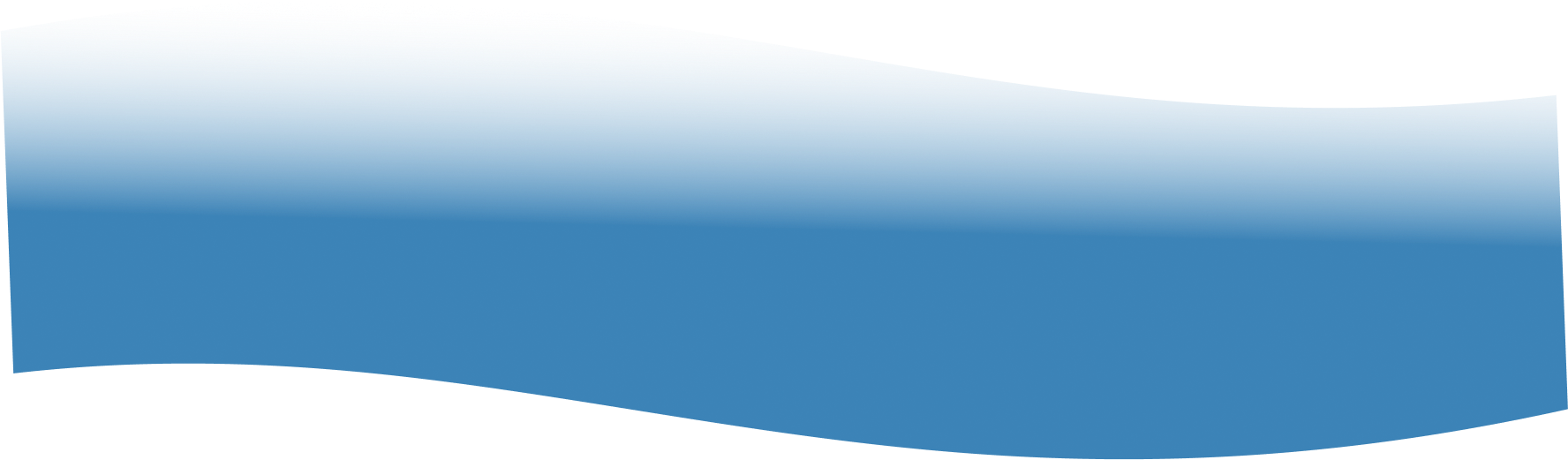

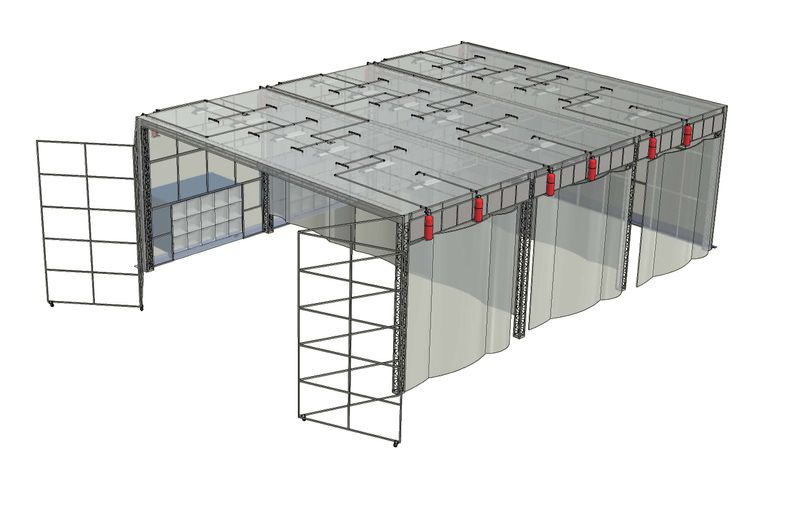

Duroair has designed and engineered the most flexible and efficient clean air systems in the market — the patented six-stage DuroPure™ industrial air filtration system paired with the retractable DuroRoom™ enclosure creates a lean manufacturing layout where it is needed.

Our plug-and-play modular system is designed to isolate processes in any work cell and filter hazards like hexavalent

chromium, isocyanates, dust, or VOCs, ensuring worker safety, saving time, and maximizing your bottom line.

8 Reasons WHY Customers Choose Duroair

Gain Flexibility

Save Money

Save Time

Increase Flexibility

Maximize Space

Make the Work Day Easier

Stay Compliant

Bring Clean Air to the Workplace

Efficient Light Transmission for Clean Air Solutions

Our retractable enclosures feature premium vinyl fabric with 95% light transmission, reducing the need for supplemental lighting. Designed for clean air environments, they ensure energy efficiency and superior visibility.

How The 6-Stage Airfiltration System Works

The first three stages capture particulates, including hexavalent chromium and particulate isocyanates. The air filtration system places less

expensive filters in front of more expensive, technically-advanced filters to protect them and extend filter life.

The third stage filter can be changed to accommodate Merv15, HEPA, NESHAP 319 standards, depending upon needs. This provides the

manufacturing flexibility to do different operations in the enclosure.

The next three-stage gas filtration process includes photocatalytic oxidation (PCO) and UV light to separate and

destroy VOCs. Carbon adsorbs contaminants and UV light destroys VOCs.

Stage 1

captures particulates to 10 microns in size

Stage 2

captures particulates to 5 microns in size

Stage 3

captures particulates to 1 micron in size

Stage 4

Stage 5

Stage 6

percent of airborne particulates are safely captured and destroyed by the system through these stages, including:

Hexavalent chromium, Isocyanates, Volatile Organic Compounds

Compliance

The six-stage DuroPure system meets compliance requirements of:

Our Systems Provide:

Flexibility

Move the enclosure not the workpiece.

Streamlined Workflow

Need a controlled environment for mechanical assembly? Duroair can design a clean air solution and integrate it into your plant layout.

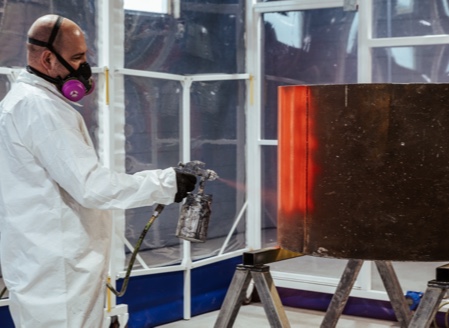

Integrate a 3 in 1 enclosure into current work cells. The flexibility enables production needs to determine its use. Use as one large cell or as 2 or 3 smaller cells.

Integrate a 3 in 1 enclosure into current work cells. The flexibility enables production needs to determine its use. Use as one large cell or as 2 or 3 smaller cells.

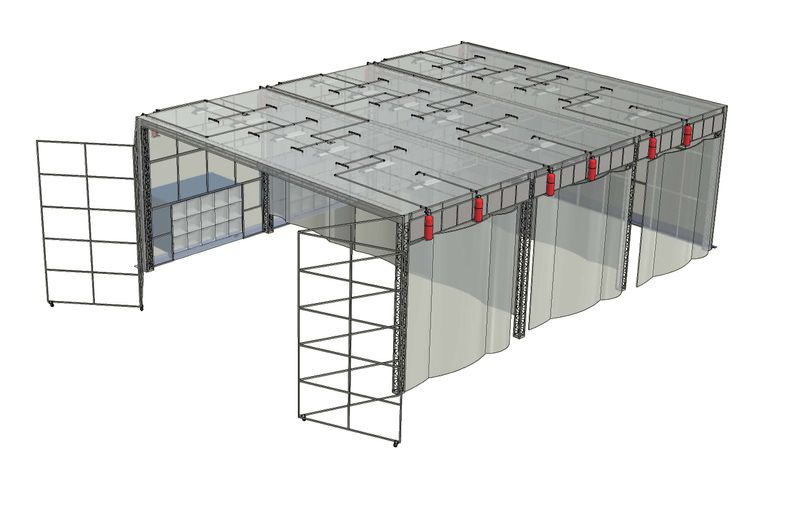

Retracts in minutes

When painting and/or prep work is completed, the enclosure can be retracted and stored at a fraction of its functional space. Or, can move to be used in an alternate location.

Duroair's Engineering Ingenuity

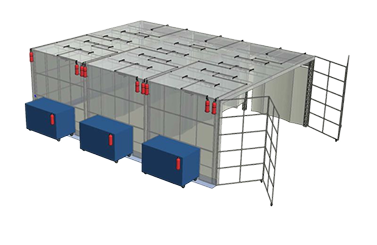

Duroair has taken its engineering ingenuity to a new level by designing a multi-chamber booth that accommodates up to three separate clean-air operations at the same time.

Flexible Setup Options to Cater Your Different Needs

The three chambers can be used independently, or one or both of the interior curtains can be opened so that one or two functions can be performed. Easily prep, paint, or coat three workpieces at the same time!

1-1-1 ratio for three separate operations.

In the case of prep work, painting, and coating, the workpiece is moved the shortest possible distance for the next function.

2-1 ratio for two operations.

This can eliminate or reduce backlogs, especially since some functions require more time than others.

1 single operation in the entire space.

This accommodates a larger workpiece, such as the wing of an aircraft, an entire wind turbine, or a large engine workpiece.

1-1-1 ratio for three separate operations.

In the case of prep work, painting, and coating, the workpiece is moved the shortest possible distance for the next function.

2-1 ratio for two operations.

This can eliminate or reduce backlogs, especially since some functions require more time than others.

1 single operation in the entire space.

This accommodates a larger workpiece, such as the wing of an aircraft, an entire wind turbine, or a large engine workpiece.

With Duroair, Eliminate Outsourcing of One or More Functions

The flexibility provides opportunities.

More easily manage multiple projects that all involve surface prep, sanding, painting and/or coating.