DuroDeployable™

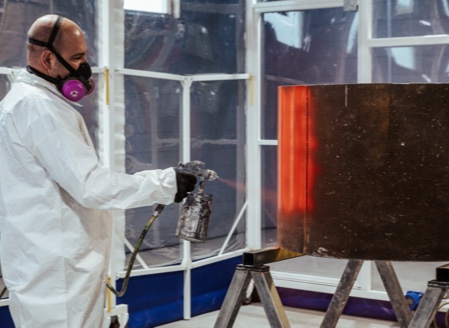

DuroDeployable™ is the rapid-deploy, portable paint booth for creating safe, controlled, compliant environments for military maintenance operations in garrison or while deployed. By combining the patented DuroRoom™ retractable enclosure and the DuroPure™ air filtration system, DuroDeployable mitigates exposure to hexavalent chromium, isocyanates, and VOCs for safe and compliant spray operations. It can be easily moved from garrison in 1-40’ High Cube MILVAN or 2-20’ High Cube MILVANS — anywhere a safe, compliant environment is required.

Designed around the Department of Defense’s (DoD) maintenance requirements, DuroDeployable helps increase operational readiness. With its plug-and-play, generator-ready construction, it can be fully operational within one hour with 3-4 service members.

Key Features

Cost Savings

- Eliminates the cost of building a new permanent paint booth or new infrastructure within a hangar or facility.

- Recirculates clean, filtered air into the workspace. No need to vent to the exterior, thereby reducing energy costs.

- Saves valuable footprint space, thanks to its small, retractable design.

Reduces Lead Times From Install to Deployment

- DuroDeployable is a generator-ready paint booth for rapid plug and play.

- Each DuroDeployable comes with a 25′ whip pre-installed, which reduces installation time. Customer electrician can add a plug to the end of the whip or remove if desired.

Designed for Personnel and Process Safety

- For user safety, DuroDeployable includes a UL/ULC listed control panel and 1’’ air solenoid interlocked with a fan.

- Equipped with a VOC monitor to monitor air levels when leaving the exhaust. It is interlocked with spray air.

- If VOCs go over the Time Weighted Average Exposure limit (50ppm), the air to the spray gun will shut off but the fans will continue to run with the filters cleaning the air.

- Comes with a fused control panel to reduce exposure to electrical hazards.

- Electrician will only need to drop power to the panel.

- System is sized to maintain over the minimum 100 linear feet per minute at the intake filters, therefore keeping the conditions well below the 25% lower explosion limit.

Meets Compliance and Air Quality Standards

- Meets compliance standards such as:

- NESHAP 319 – Testing protocol where chromate paint is mimicked. This test verifies an air filtration system meets minimum efficiency requirements.

- DCPH-A – (Defense Centers for Public Health – Aberdeen) tested and verified by U.S. Army Engineers and Industrial Hygienists.

- OSHA – VOC monitor ensures the VOC level does not rise above the allowable amount in an 8-hour time period (50ppm).

- DuroDeployable also exceeds many compliance standards, including containment of particulate levels for safeguarding personnel against hexavalent chromium.

Technical Specifications

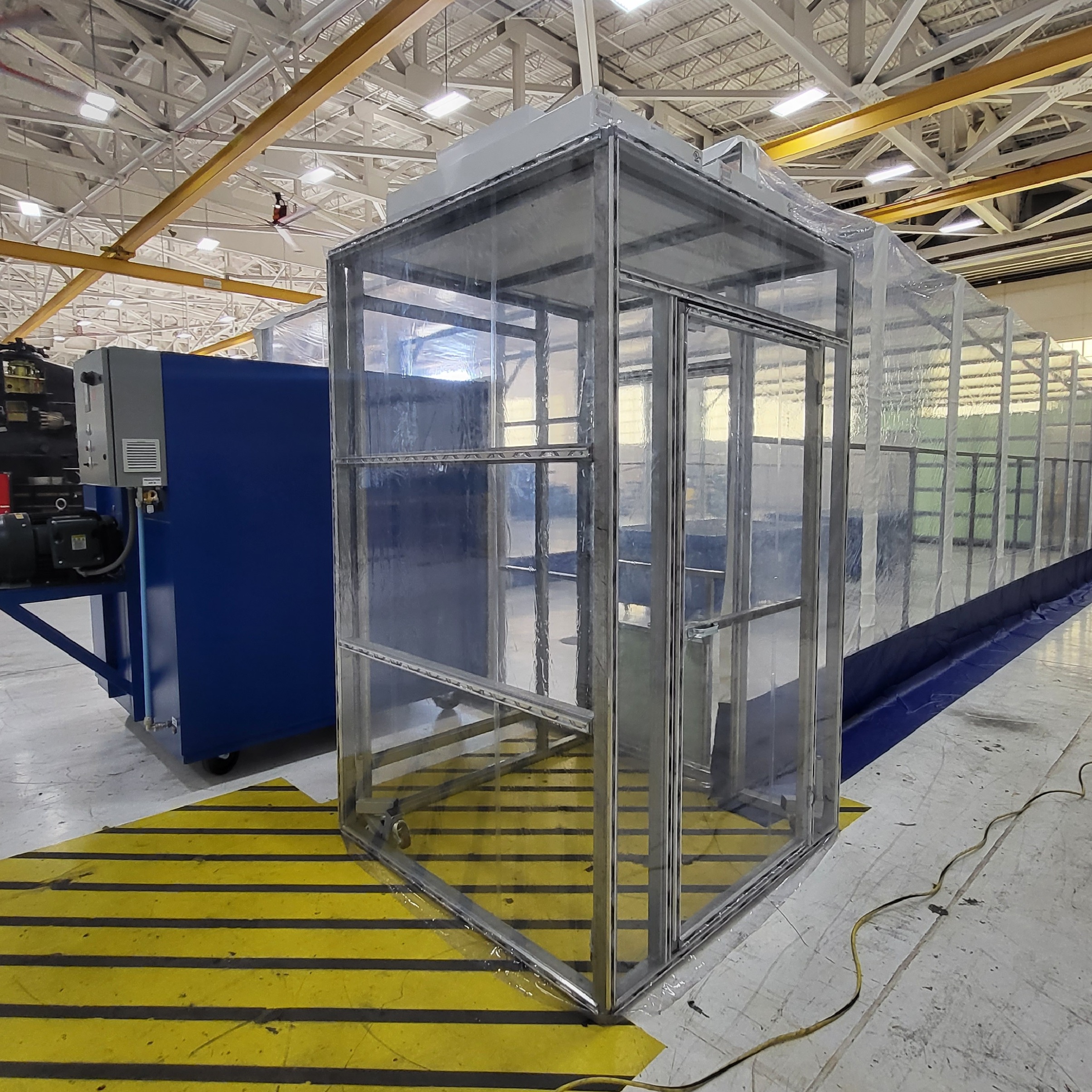

- The standard size enclosure is 8’H X 18’W X 40’L with an 18,000 CFM DuroPure unit (includes 25’L whip).

- Utilizes the DuroPure and DuroRoom systems.

- Full face sliding curtain or barn door access to retractable enclosure.

- Entry is via an anteroom.

- The slightly negative pressure paint booth has an airflow of over 100 FPM at intake filters.

- Designed to fit into one 40’ High Cube or two 20’ High Cubes/MILVANs.

- Duroair systems exceed ACHIH TLVs and OSHA standards and are tested and verified by DCPH-A.

- Training and maintenance best practices included with purchase.

Duroair Products for DuroDeployable

Our products are customized to meet your exact needs and specifications ensuring both a safe and productive work environment.