DuroCap™

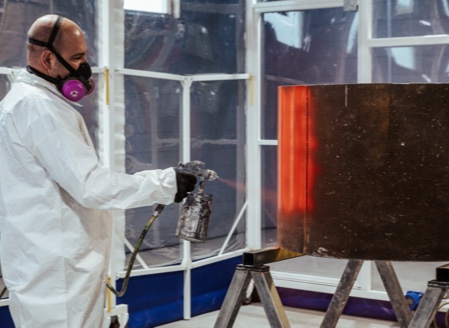

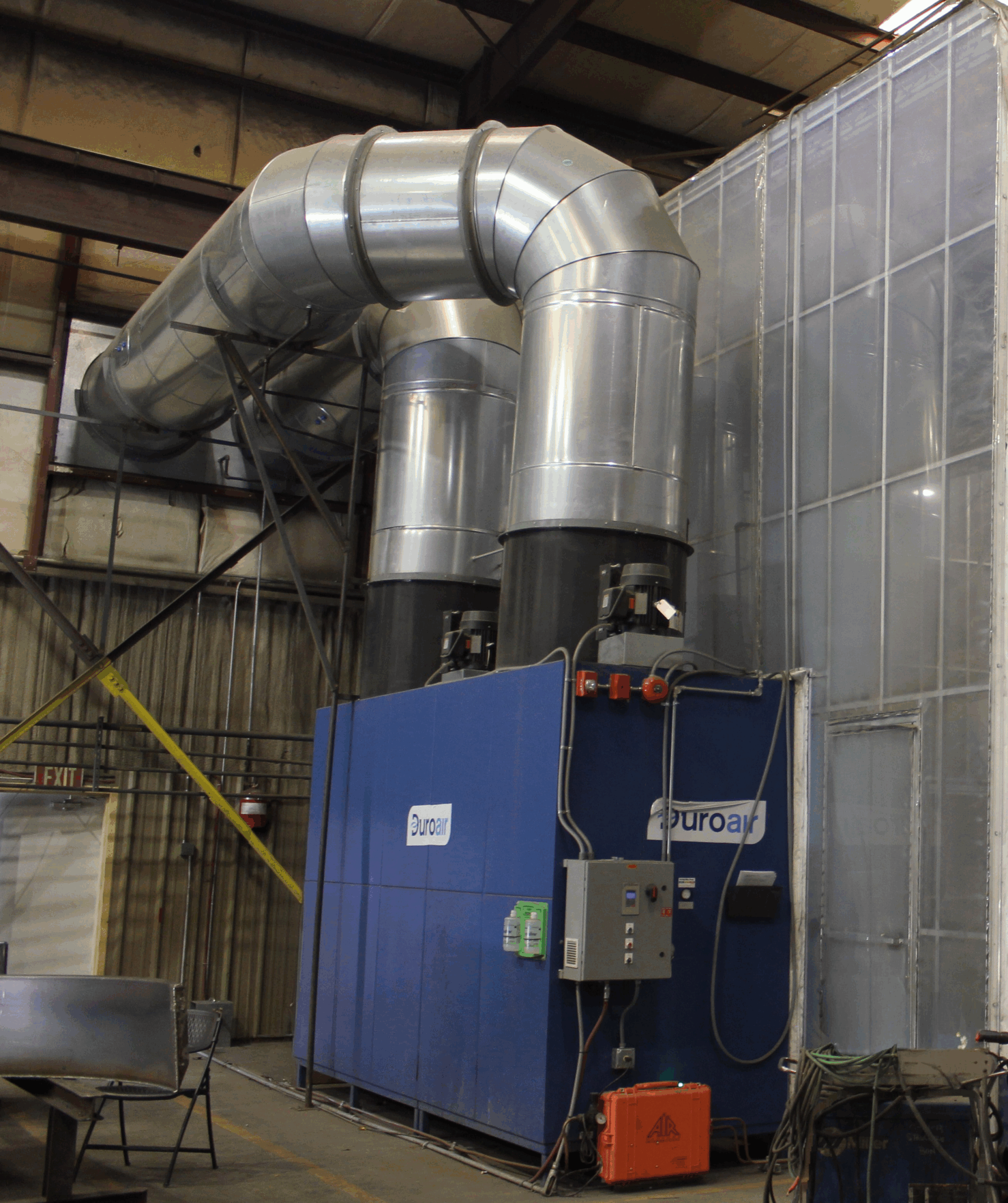

DuroCap™ is the vented, modular, air filtration system that’s easily customizable for extracting dusts, fumes, and gasses, creating a clean-air envelope around your oversized work pieces. Its 2-stage filtration removes 99.4% of all air pollutants for a contaminant free portable workstation during sanding, grinding, coating and painting. DuroCap has an enhanced 3rd stage filter when a vented option that meets NESHAP 319 is required.

Pair it with:

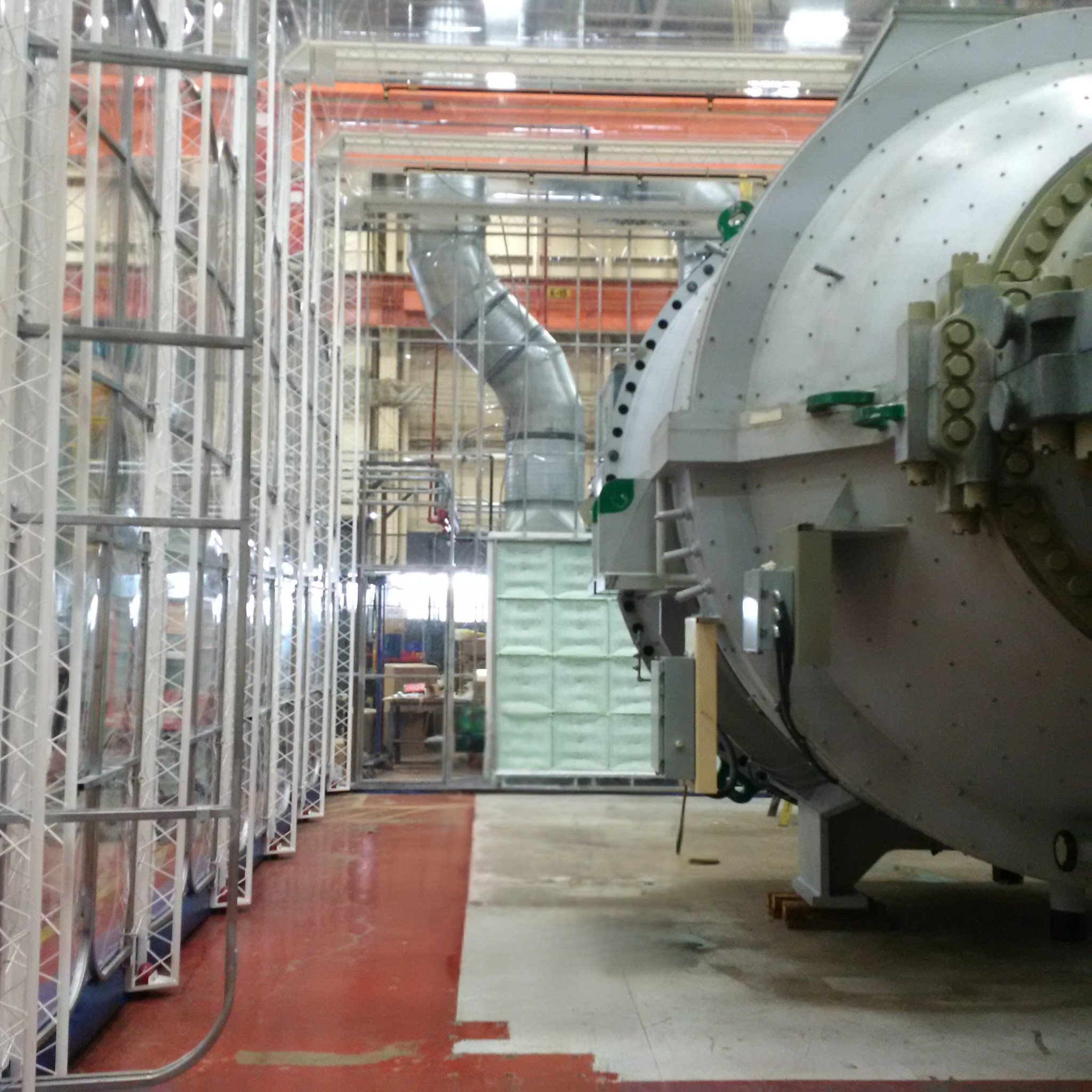

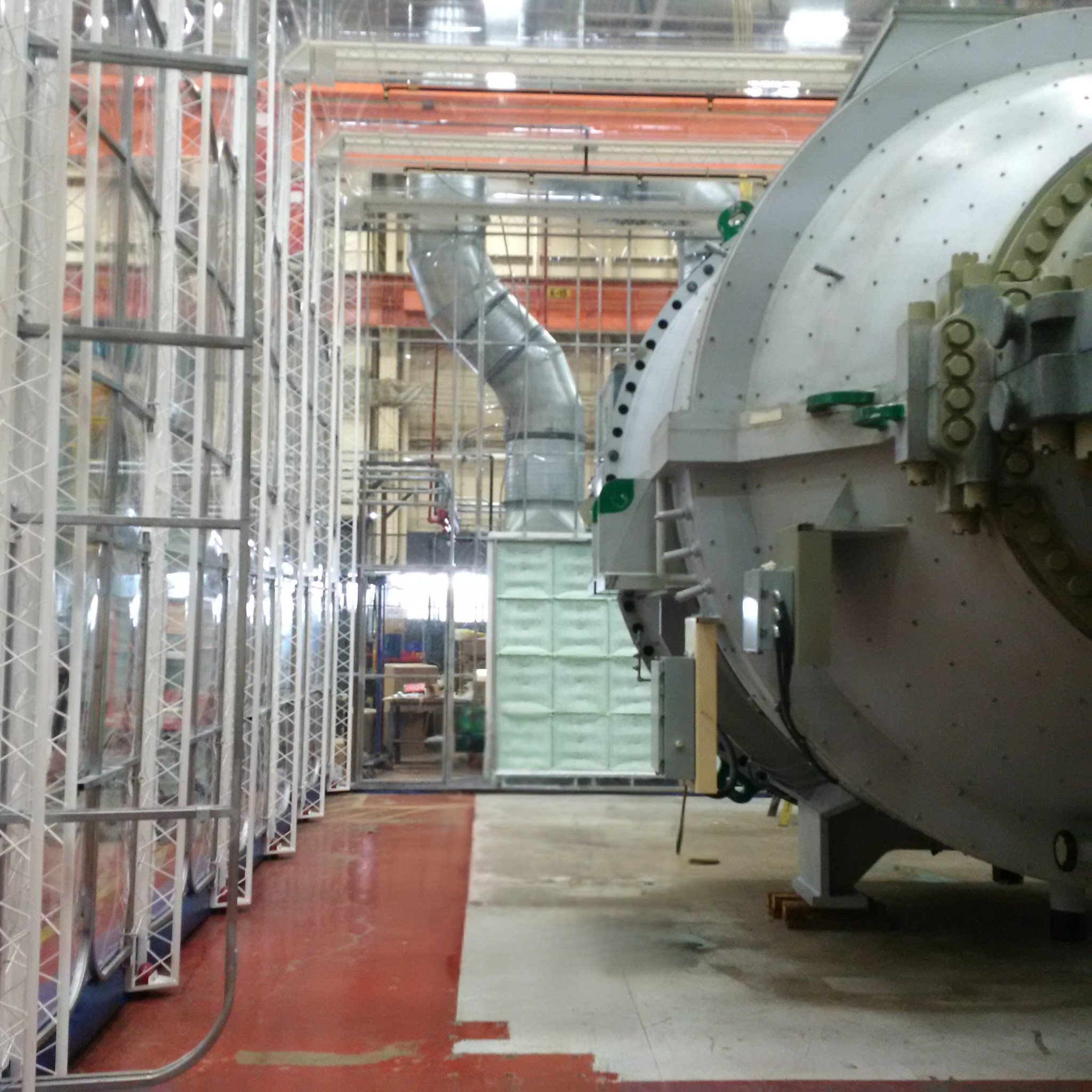

- DuroRoom™ to create a clean air envelope around workpieces for a contaminant free retractable work station.

Key Features

Easy Assembly

Comes fully assembled with a pre-wired control panel (lockable fused disconnect and C/UL/US Listed). Combined with a DuroRoom, the system depending upon size, can be installed in two to three days with a small crew.

Taper Draft Airflow Technology

Directs air down the center of the enclosure to maximize control of overspray, keep the sidewalls clean, and speed drying time.

Meets/Exceeds CFM Requirements

Engineered airflow requirements from 13,500 CFM to 120,000 CFM and beyond, to achieve airflow over 100 FPM at the intake filter face and ensure airflow remains below code requirements of 25% of the LEL (lower explosion limit).

Vented Solution

Suitable for production painting and paints over 2.8 lbs VOCs per gallon.

Variable Frequency Drive

Energy-efficient VFD with adjustable air speeds, doubles as a soft starter to eliminate the need for a motor starter.

Fire Suppression

Designed by Kidde Badger for protection of exhaust systems and the enclosure, while meeting NFPA 17 standards and is UL listed. Wet or dry systems are available depending upon requirements. Wet systems are for non-retracting only.

Technical Specifications

- Single phase 220V and three phase 208/230/460/575V available upon request.

- Built-in air regulation control with production air interlocked/ fans for safety.

- Exhaust system creates a negative pressure vacuum seal around the DuroRoom to ensure no contaminants or VOCs are released into the main work environment and are directed through the exhaust system’s filters to the exterior.

- Non-sparking aluminum blades, sized 12” to 60”, with 1/2hp to 10hp motors dependent on required airflow.

- Pairs with enclosure made of a durable fire rated PVC vinyl meeting the requirements of NFPA 701.

- System exhausts air to the exterior and requires ducting and make-up air.

Duroair Products for DuroCap

Our products are customized to meet your exact needs and specifications ensuring both a safe and productive work environment.