DuroPure™ Non-Vented Filtration | Industrial Air Purification

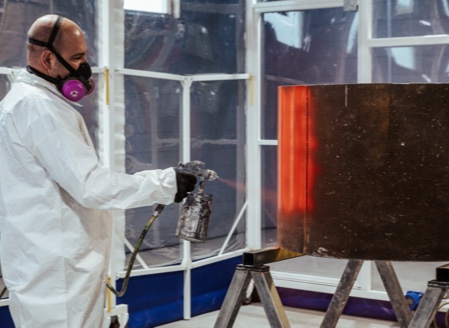

DuroPure™ is the world’s first, indoor air filtration system that goes beyond OSHA compliance to capture 99+% of airborne particulates like hexavalent chromium, VOCs, and isocyanates, and recirculates clean air back into the workspace. With built-in casters and no ducting required, it moves easily with your workflows and is plug and play or deployable.

Pair it with:

- DuroRoom™ to create a clean air envelope around workpieces for a contaminant free retractable work station.

Key Features

Patented Six-Stage Filtration

Multi-stage particulate collection and multi-stage gas collection with carbon adsorption and UV PCO (photocatalytic oxidation) technology

Taper Draft Airflow Technology

For maximum velocity around products painted in DuroRoom enclosure and minimized accidental overspray and enclosure wall residue

Meets/Exceeds CFM Requirements

Engineered per airflow requirements from 13,500 CFM to 200,000 CFM and beyond, to achieve airflow over 100 FPM at the intake filter face and ensure airflow remains below code requirements of 25% of the LEL (lower explosion limit)

Safety Features Production

Air interlocked fans with fresh breathing line supplied

Exhaust System

Creates a negative-pressure vacuum seal to contain particulates and chemical contaminants

Fans

Non-sparking, reverse incline fan wheels, in sizes 18” to 35”, 5hp to 25hp motors dependent on airflow requirements, with 3.5” static pressure

Optional LEL Monitor

If LEL monitor reaches “set point” the air solenoid is shut down to ensure no more VOCs are produced

VOC Monitor

VOC C-21, solid-state gas monitor capable of sensing a variety of gases and vapors (C-21 is for solvent vapors, etc.) and the system shuts down spray gun if the VOC monitor is triggered

Fire Suppression

Designed by Kidde Badger for protection of exhaust systems and the enclosure, meets NFPA 17 standards and UL listed

Defense Centers for Public Health – Aberdeen (DCPH-A) tested and verified by Army Engineers and Industrial Hygienists

The DuroPure system mitigates exposure to hexavalent chromium, isocyanates and VOCs, meeting HQDA’s mandate

Technical Specifications

- Recirculating, non-vented solution.

- Patented, Six-stage filtration.

- Three (3) stages of particulate collection; captures paint particulate including hexavalent chromium and particulate isocyanates. Final filter exceeds NESHAP 319 Three (3) stage gas filtration, captures isocyanates in gas stage and destroys VOCs.

- Two (2) stages of activated carbon filtration. Over 70lbs of carbon for every 2000 CFM.

- UV light with PCO (photocatalytic oxidation). Converts organic pollutants into the carbon dioxide & water.

- No ducting or makeup air required.

- Plug and Play and can be generator ready.

- Robust CFM to meet airflow requirements @ 100 FPM, less than 25% LEL is maintained.DCPH-A tested, confirmed and verified.

- System is monitored. VOC monitor will shut down system if ACGIH limits are surpassed.

For technical information, download our DuroPure fact sheet!

Duroair Products for DuroPure

Our products are customized to meet your exact needs and specifications ensuring both a safe and productive work environment.