Advanced, Affordable Clean-Air

Solutions for Military MRO

Serving All U.S. Military Branches: Army, Navy, Marines, Coast Guard, AirForce, Space Force, National Guard, and Reserves

From U.S. military bases to military operations around the world, operational readiness depends on flexible, reliable maintenance, repair, and operations (MRO). But MRO tasks like sanding and painting can release dangerous, airborne hexavalent chromium and VOCs. How do you isolate and contain these threats while ensuring MRO flexibility?

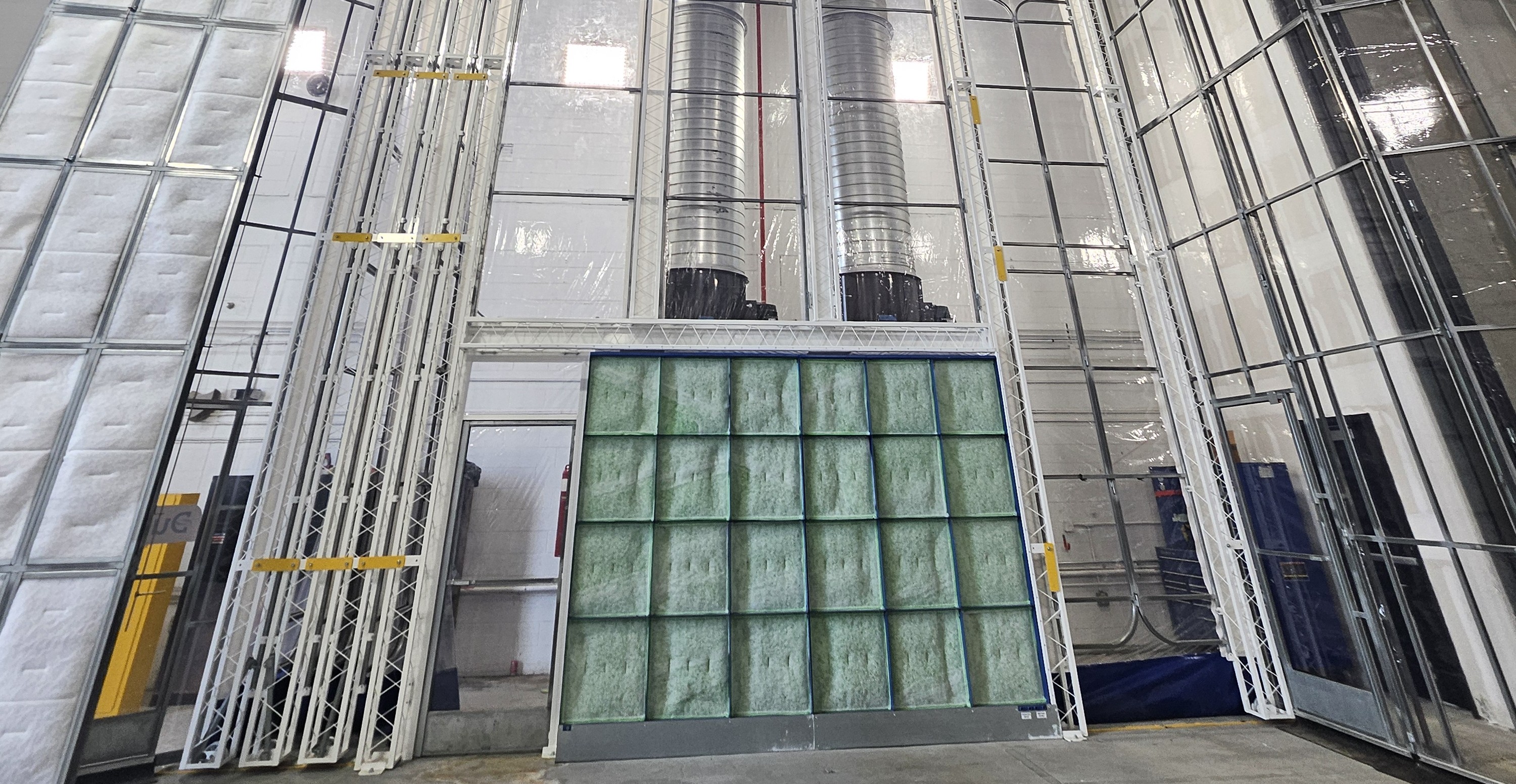

Fortunately, Duroair has created a new formula for clean-air flexibility by combining portable industrial air filtration technology with retractable enclosures. Our retractable enclosures isolate, contain, and protect processes as engineered filtration mitigates harmful contaminates for a compliant, tested, and verified clean air solution.

Plus, Duroair's flexible, modular, and retractable solutions are more affordable than designated paint rooms and work spaces and move with military maintenance workflows. They're a cost-effective way to facility material handling challenges associated with coating operations, surface prep, mechanical assembly, isolation rooms, NDT, dust collection, and ISO clean rooms.

Designed Around DOD Maintenance Requirements for Cost, Operational Readiness, and Safety

Our modular, industrial air filtration systems bring clean air to each rapid-moving, military manufacturing operation. For example, our retractable DuroRoom™ combined with our DuroPure™ non-vented air filtration easily moves with grinding, painting, or sanding assignments. Each system can be engineered to accommodate large components for jets, MRAPs, or submarines, creating a cost-effective alternative to conventional systems.

Ensure Service Member Health & Safety

Reduce Maintenance Costs

Increase Operational Readiness

Ensure Service Member Health & Safety

- Protection is tested, verified, and confirmed by the DCPH-A.

- Mitigate exposure to hexavalent chromium, isocyanates, heavy metals, and VOCs. Meets the HQDA mandate.

- Isolate toxic processes from other service members in a shared space.

- Systems meet CFM requirements. VFD allows for control of airflow. Airflow is 100 FPM. At these air speeds the requirement for less than 25% LEL is met.

- Each system is monitored to verify OSHA limits are maintained.

- OSHA, ACGIH, NFPA Compliant.

Containment + Filtration = MRO Flexibility and Operational Readiness

Use DuroRoom Containment to:

- Simplify material handling with access to overhead cranes

- Repair components to complete aircraft or ground equipment

- Contain decontamination processes and NDT

- Maximize floor space. It retracts to 20% of its extended length

- Customize with retractable sizes up to 50'H x 65'W in any length

- Customize as a fixed system up to 50'H x 150'W in any length

- Simplify workflows and save valuable hours

- Multiply productivity in shared larger spaces by creating contained work cells

- Create Plug-and-Play transition rooms (i.e., anterooms or gowning rooms)

Combine with DuroPure Filtration for:

- Recirculating, non-vented, six-stage filtration.

- Robust CFM to meet airflow requirements @ 100 FPM, less than 25% LEL is maintained.

- Three (3) stages of particulate collection. It captures paint particulate including hexavalent chromium and particulate isocyanates. Final filter exceeds NESHAP 319.

- Three (3) stage gas filtration; captures isocyanates in gas stage and destroys VOCs.

- Two (2) stages of activated carbon filtration. Over 70lbs of carbon for every 2000 CFM.

- UV light with PCO (photocatalytic oxidation). Converts organic pollutants into carbon dioxide and water.

- No ducting or makeup air is required.

- Plug and Play and can be generator-ready.

- DCPH-A tested, confirmed, and verified.

- Each system is monitored.

Specialized Solutions for Your MRO Needs

DuroDeployable™

DuroDeployable™ exceeds ACHIH TLVs and OSHA standards and is tested and verified by DCPH-A.

Read more

DuroClean™

Pair DuroClean™ with DuroRoom for on-demand clean rooms and isolation rooms whenever and wherever needed.

Read more

DuroRoom™

Use DuroRoom for dust control, coating, clean rooms, isolation rooms, anterooms or gowning rooms, and non-destructive testing environments.

Read more

DuroPure™

DuroPure recirculating exhaust units are used for coating and surface preparation applications. It does not require ducting or ventilation and does not require changes to infrastructure.

Read more

DuroCap™

DuroCap™ pairs with DuroRoom to create a clean air envelope around workpieces for a contaminant-free retractable workstation.

Read more

TOP 10 Ways Duroair Supports Mission-Critical Readiness for Military Bases

Between manufacturing, MRO, and prototyping, you don’t have time to rearrange your entire facility with the dedicated space and ductwork to shield your employees from airborne contaminates during sanding and painting. You need portable, clean-air solutions for the mission readiness, flexibility, and reliability required of your people and mission-critical equipment. Here are 10 ways Duroair supports mission readiness with portable containment and industrial air filtration systems.

Increases Readiness

Our systems are deployable capital equipment. They can be designed to be compatible with Deployable Rapid Assembly Shelters currently in use by the military. The system is plug and play and can be deployed where needed.

Protection of Service Members

Provides Options Through Mobility

Boosts Repair Agility

Reduces Energy Costs

Meets Any Size Requirement

Eliminates Outsourcing

Aids in Efficiency for High-Demand Operations

Accommodates Large Workpieces

Saves on Capital Expenses